Zirconium Industrial Venturis, Zirconium Venturi Manufacturer, Zirconium Venturi Exporter, Zirconium Venturi Supplier in Mumbai, India.

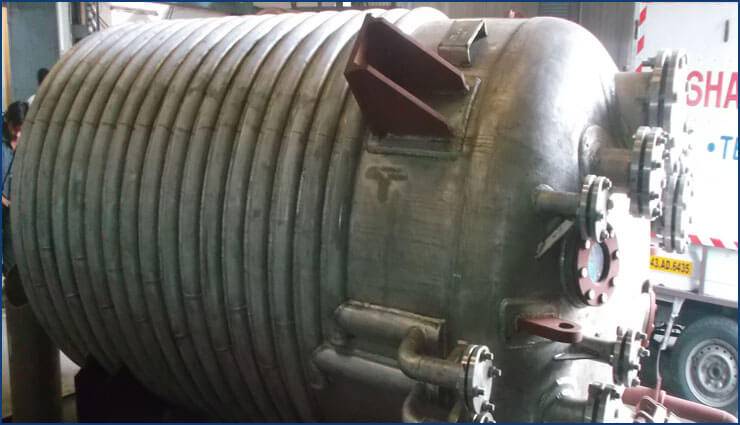

Zirconium Venturi is made from alloys that offer corrosion resistance in harsh corrosive environments. An apparatus used for measuring a flow rate of gas or mixing fine spray of liquid with gas is known as a ventuary. Vapor is entered through an opening to a ventuary channel with low pressure. This pressure differential is used to measure the flow of fluid. Due to its stable physical state and electron configuration zirconium can be made into many equipment or application in industries.

Zirconium also renders improved function, machinability, toughness, ductility and workability of iron and other metals. One main reason is that zirconium can absorb certain gases such as oxygen, hydrogen, and nitrogen in extremely surprising ways. Thus, this metal can resist the corrosion effect caused by oxide or nitride by evading the effect of weak acids and acidic salts. Because of these countless features of zirconium has become an important element in many industries. Zirconium improves the efficiency of nuclear reactors by its strong corrosion resistance and thermal heat absorbing properties. Moreover, does not react readily with other elements due to its hard nature.

Zirconium Venturi, Zr Venturi, Zr 702 Venturi, UNS R60702 Zirconium Venturi Stockist, Zr 704 Venturi, Zr 705 Venturi, Zirconium Venturi Manufacturer in India.

Thus, zirconium can be used generally as processing equipment, equipment, and machines as they can perform competitive functions as well.

In the production of zirconium, the quality control methods implemented in the production process are typical Statistical Process Control (SPC). It becomes necessary to maintain the process control of production to maintain proper transformation of these products. Quality assurance of this Zirconium Venturi involves controlling and tracking of determined variables according to the end product requirements.

One can deal with Tinita Engineering to have profitable deal.

Advantages of Zirconium Venturi:-

- Long-term validity as compared to other materials

- Cost saving if it is well maintained

- Corrosion resistant

- High heat transfer efficiency

- Eliminates expensive downtime due to equipment failure

- Good heat conductor with Welding properties

Types Of Zirconium Venturi

- Zirconium Zr 702 Venturi

- UNS R60702 Venturi

- Zirconium Zr 704 Venturi

- Zirconium Zr 705 Venturi

Chemical Composition :-

| Zirconium Chemical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade | Zirconium + Hafnium (min) | Hafnium (max) | Iron + Chromium | Tin | Hydrogen (max) | Nitrogen (max) | Carbon (max) | Niobium | Oxygen (max) |

|

Zirconium Zr 702 |

99.2 | 4.5 | 0.2 max | - | 0.005 | 0.025 | 0.05 | - | 0.16 |

|

Zirconium Zr 704 |

97.5 | 4.5 | 0.2-0.4 | 1.0-2.0 | 0.005 | 0.025 | 0.05 | - | 0.18 |

|

Zirconium Zr705 |

95.5 | 4.5 | 0.2 max | - | 0.005 | 0.025 | 0.05 | 2.0-3.0 | 0.18 |

Mechanical Properties :-

| Zirconium Mechanical Properties | ||||

|---|---|---|---|---|

| Grade | Melting point | Tensile strength | Yield strength | Elongation |

| Zirconium | 1843°C (3350°F) | 330 MPa, 47900 psi | 230 MPa, 33400 psi | 32% |

Exports

Tinita Engineering (P) Ltd. exports Zirconium Venturis with ASME 'U' stamp to SAUDI ARABIA, UAE, KUWAIT, QATAR, OMAN, IRAN, UNITED STATES OF AMERICA, UNITED KINGDOM, AUSTRALIA, SOUTH AFRICA, MEXICO, TURKEY, FRANCE, EUROPEAN UNION, NEW ZEALAND, BAHRAIN, OMAN, YEMEN, LEBANON, SPAIN, INDONESIA, MALASIA, LEBANON, IRAQ, IRAN, EGYPT, MADAGASKAR, SRI LANKA, DENMARK, POLAND, ITALY, BRAZIL, SINGAPORE AND NETHERLANDS.

Enquiry

If you have any Inquiry in regards to Zirconium Venturis please contact us on +91-22-50441001 or email us on tinita@tinita.in. Our Experts can guide you on the same and inform in regards to other various metals fit for your applications.